Our technology, your device

As an antimicrobial surface technology company, Orthobond understands the investment of time and money that is required to develop a medical device. We are also more than familiar with the often-arduous process it takes to receive FDA clearance or approval for these devices.

These two factors were top of mind when we began developing Ostaguard™ more than 13 years ago. Our challenge: To create an antibacterial surface coating that could be applied to an implantable device without having to make alterations to its design. By achieving this goal, Orthobond preserves the investment manufacturers have already made in the development and FDA clearance or approval of their devices—while giving them an antibacterial edge.

Ostaguard is a first-of-its-kind antibacterial surface coating—as well as the first-of-its-kind to be granted De Novo classification by the FDA with an initial application in the field of orthopedic spinal implants. After being tested on numerous surfaces against 12 microbes that represent nearly all cases of device-related infections, Ostaguard was shown to be highly effective in killing multiple strains of bacteria that could come in contact with an implant in the operating room. An FDA-cleared permanent spinal implant with Ostaguard technology safely and effectively kills bacteria by mechanically rupturing pathogens—and without the use of antibiotics.

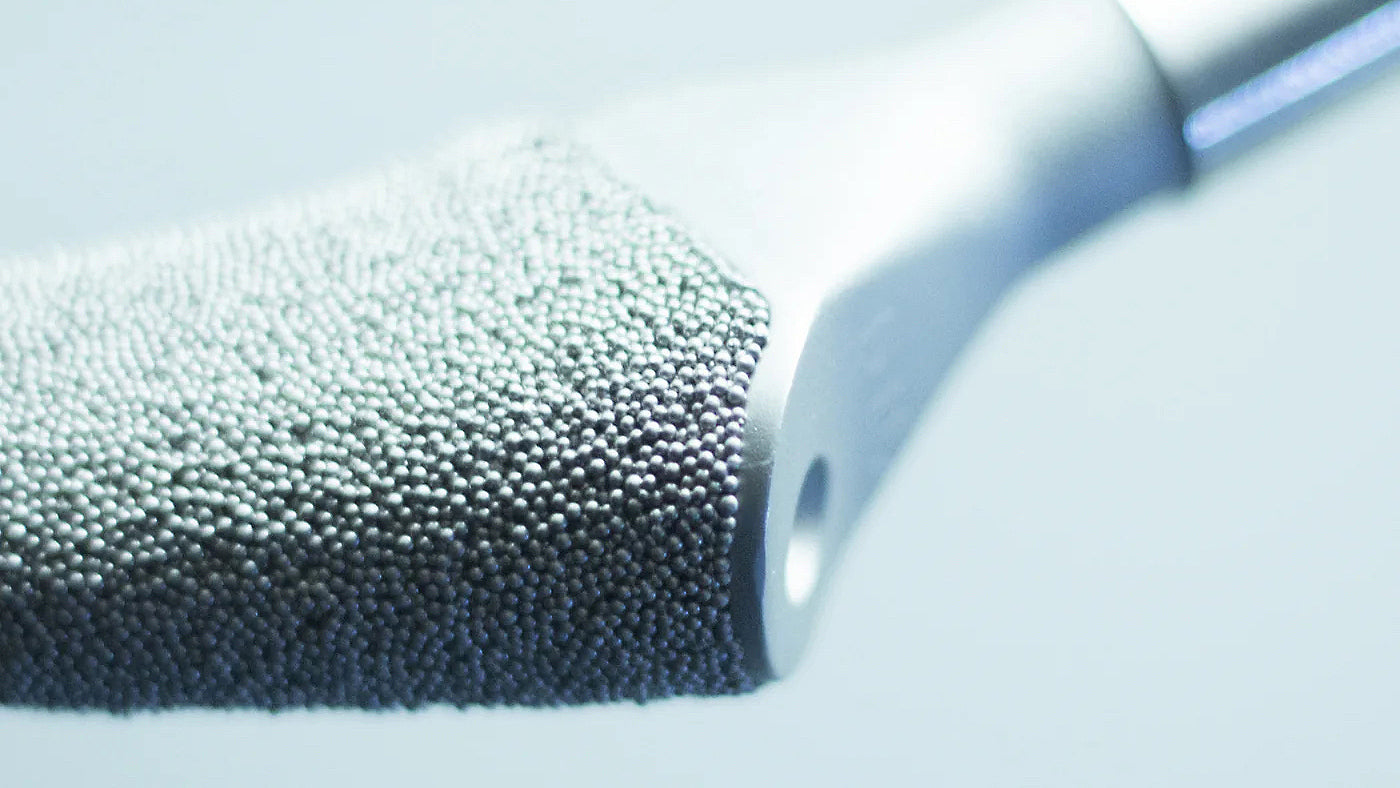

Measuring less than 100 nanometers thick, Ostaguard does not interfere with an implant’s function or integrity. Ostaguard allows the components of any device to perform as intended and will not contribute to implant failure. In fact, Ostaguard reduces bacterial contamination that occurs before the device is placed in the patient—and this bacterial contamination is a primary cause of device failure.*

To be clear, Orthobond is not a device company. As an antimicrobial surface technology company, we treat other companies’ devices. However, the actual “treatment” of your device is just one step of the process.

In addition to our development expertise for applying Ostaguard to a new device,Orthobond’s seasoned regulatory and compliance experts manage the path to FDA clearance or approval. With unparalleled industry experience, our senior talent specializes in the hyper-specific niche of antibacterial technology—including its use in FDA-regulated medical devices. Our experts ensure that product technology is accurately represented by claim language to create a predictable regulatory pathway. We have also developed proprietary regulatory management, guidelines, protocols, and testing controls that consistently meet required benchmarks to help Ostaguard-coated products move swiftly along the approval path.

When Orthobond treats devices with the Ostaguard surface, we treat them as if they were our own. This includes ensuring stability between the time a device leaves the lab and is implanted into a patient. Our team has replicated the devices’ journey from the lab to the operating room, simulated shipping and warehouse conditions, and assessed compatibility with sterilization techniques—all in the name of stability.

Orthobond is currently working with partners in a variety of areas, including spine, trauma, oncology, and neuromodulation. Beyond the medical space, we foresee our antimicrobial surface treatment becoming the gold standard for textiles, high-touch surfaces, and everyday product packaging.

Contact Orthobond today to learn how Ostaguard can give your implantable devices an antibacterial advantage—and make you among the first to help save thousands of lives every year by minimizing implant contamination.

* Zimmerli W (Interdisciplinary Unit of Orthopaedic Infections, Kantonsspital Baselland, University of Basel, Liestal, Switzerland). Clinical presentation and treatment of orthopaedic implant-associated infection(Review). J Intern Med 2014; doi: 10.1111/joim.12233 276: 111–119.